Quick Summary:

Struggling with stockouts, overstocking, or inefficiencies in your retail operations? Demand forecasting and inventory optimization solutions can help, but understanding the key challenges is the first step. This blog highlights the issues businesses face and how data-driven insights can transform operations. Curious about the future of retail? Keep reading.

In this blog, we’re going to discuss📝

- The Power of Demand Forecasting: Key Benefits and Opportunities

- How Demand Forecasting Works: Data, Models, and Adjustments

- Bridging the Gap: Integrating Forecasting with Inventory Management

- Optimizing Retail Operations: Key Features of Modern Inventory Systems

- Implementing Demand Forecasting and Inventory Optimization

- Emerging Trends and Technologies in Retail

In today’s fast-paced retail landscape, managing inventory and forecasting demand is more challenging than ever. Market demands change quickly, and businesses need to adapt or risk losing customers. Accurate demand forecasting and inventory management play a vital role in ensuring smooth operations, customer satisfaction, and financial health.

Key Challenges:

- Stockouts: When products go out of stock, businesses miss sales opportunities and risk losing loyal customers.

- Overstocking: Excess inventory ties up cash, increases storage costs, and risks products becoming obsolete.

- Operational Inefficiencies: Poor inventory practices lead to wasted time, higher costs, and reduced productivity.

By focusing on demand forecasting and inventory optimization, retailers can solve these challenges. These tools help businesses maintain the right stock levels, meet customer expectations, and minimize costs.

The Power of Demand Forecasting: Key Benefits and Opportunities

In retail, anticipating customer demand is the key to staying competitive. Demand forecasting uses data to predict future needs, enabling businesses to plan effectively and stay ahead of market trends. This strategic approach offers significant advantages for inventory management, customer satisfaction, and overall business efficiency.

Key Benefits:

- Optimized Inventory: Accurate forecasts ensure the right products are always in stock, improving cash flow and reducing waste.

- Cost Savings: By minimizing excess inventory, businesses lower storage, insurance, and handling costs.

- Better Customer Experience: When popular items are consistently available, customer satisfaction and loyalty increase.

How Demand Forecasting Works: Data, Models, and Adjustments

Demand forecasting combines data analysis and predictive models to make accurate predictions. It’s a multi-step process that turns raw data into actionable insights for better inventory decisions.

Step 1: Data Collection

Gather relevant data such as past sales records, customer preferences, and market trends. For example, a retailer selling winter jackets might use historical sales data while considering weather patterns and seasonal promotions.

Step 2: Data Analysis

Analyze collected data using statistical methods or machine learning models. These tools identify patterns like seasonality or the impact of promotional campaigns. For instance, umbrella sales tend to rise during rainy seasons, allowing businesses to plan timely restocks.

Step 3: Adjustments

Adjust models for unexpected changes, such as sudden weather events or competitor actions. For example, a surprise cold snap may increase demand for winter coats, requiring quick inventory updates to avoid stockouts.

By refining forecasts, businesses align their inventory with real-world demand, improving efficiency and customer satisfaction.

Bridging the Gap: Integrating Forecasting with Inventory Management

Integrating demand forecasting with inventory management systems creates a seamless operation where stock levels are automatically adjusted based on predictions. This alignment enhances efficiency, reduces manual errors, and ensures businesses stay ahead of demand fluctuations.

Real-Time Updates

Live data integration ensures stock levels are always accurate, reducing the risk of stockouts or overstocking.

Automated Replenishment

Advanced systems automatically reorder products based on forecasted needs, saving time and effort.

Centralized Tracking

Consolidating data from multiple locations into a single dashboard provides full visibility and better decision-making.

Optimizing Retail Operations: Key Features of Modern Inventory Systems

Modern inventory systems are designed to meet the demands of today’s dynamic retail environment. These systems combine advanced technology and demand forecasting to maintain optimal stock levels and adapt to changing market conditions.

Real-Time Tracking

Continuous monitoring of inventory across locations provides accurate stock data, enabling informed decisions.

Automated Alerts

Notifications for low stock levels or underperforming items allow proactive management.

Demand-Driven Restocking

Systems adjust restocking schedules based on forecasts to maintain balance and avoid surplus.

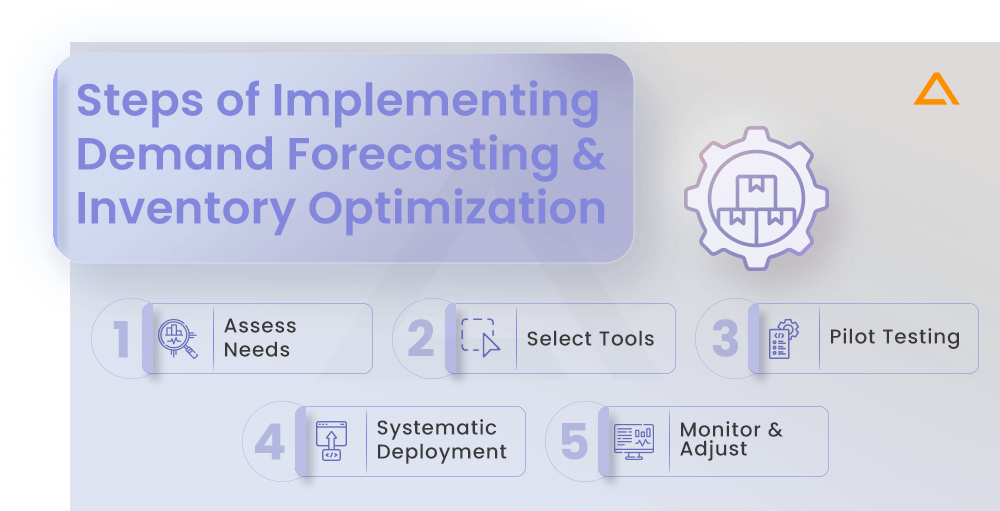

From Insight to Action: Implementing Demand Forecasting and Inventory Optimization

Implementing demand forecasting and inventory optimization requires a structured approach. By following key steps, businesses can set up effective systems that drive efficiency and results.

Step 1 – Assess Needs

Identify pain points such as frequent stockouts or overstocking. Setting clear goals helps in choosing the right tools and strategies.

Step 2 – Select Tools

Choose software that offers real-time tracking, integrates seamlessly with existing systems, and adapts to external factors like market changes or weather.

Step 3 – Pilot Testing

Test the chosen tools on a small scale to evaluate their performance and make necessary adjustments.

Step 4 – Systematic Deployment

Roll out the system gradually across all operations. Provide training for teams to ensure smooth adoption and efficiency.

Step 5 – Monitor and Adjust

Regularly track performance metrics like forecast accuracy and stock turnover rates. Use these insights to refine models and improve practices over time.

Looking for Retail IT Solutions?

Level Up Your Retail Game with Future-Ready Technologies.

Emerging Trends and Technologies in Retail

As the retail landscape evolves, emerging trends and cutting-edge technologies are transforming the way businesses operate. From advanced data analytics to AI-driven solutions in retails, these innovations are helping retailers optimize their processes, enhance customer experiences, and stay competitive in a rapidly changing market.

By embracing these new tools and strategies, retailers can better anticipate demand, streamline operations, and drive sustainable growth. The following sections explore key trends and technologies shaping the future of retail.

Predictive Analytics

Retailers are increasingly using predictive analytics to anticipate customer behavior and sales trends. This allows businesses to proactively restock items before shortages occur, ensuring a consistent product flow and minimizing lost sales opportunities.

AI and Machine Learning

Advanced AI and machine learning tools are enabling more accurate demand forecasts by analyzing large datasets. These technologies allow businesses to adapt quickly to shifting market conditions, refining forecasts as new data comes in.

Robotics and Automation

Automation is streamlining many inventory-related tasks, such as stock counting and order fulfillment. By using robotics, businesses improve speed and reduce errors, creating a more efficient and reliable supply chain.

Personalized AI Solutions

Personalized AI tools are transforming how retailers approach inventory. By analyzing customer preferences, these tools help businesses anticipate demand more accurately, leading to better stock management and stronger customer relationships.

Sustainability Practices

Eco-friendly practices are gaining traction in retail. Businesses are adopting strategies to reduce excess inventory, lower waste, and cut carbon footprints, aligning with sustainability goals while improving efficiency.

Wrapping up!

Effective forecasting and inventory optimization are essential for retail success. These practices not only improve operations and reduce costs but also enhance customer satisfaction by ensuring products are available when needed. By integrating modern systems and adopting emerging trends like AI and automation, businesses can stay competitive and ready for future challenges.